The OCPD that is installed on your equipment comes in many forms and is often forgotten about when it comes to maintenance and the importance of the protection. The OCPD is in use on every circuit and is considered to be “Normal Operation” of the electrical equipment. The 70E talks about Normal Operation in many sections and it is so important that we understand what they are saying exactly so I have explained the basic operations of protective devices below.

FUNDAMENTALS PRINCIPLES OF PROTECTIVE DEVICES

The function of protective devices in the operation of a power system is to prevent or limit damage during faults or overloads (excessive current in the circuit) and to minimize their effect on the remainder of the system. This is accomplished by dividing the system into protective zones separated by protective devices.

Any protective device must do three things to be considered a protective device; Sense, Respond, and Trip. It must perform all three, sense the current level/magnitude at all times, respond to an overcurrent condition either with time delay or instantaneous response, and finally trip the circuit and clear the fault.

It is the purpose of an electrical system to provide a continuous supply of energy to its utilization equipment at a reasonable cost. The greatest hazard to this system is a short circuit (a low-resistance connection across a voltage source or between both sides of a circuit or line, usually accidental and usually resulting in excessive current flow that may cause damage) caused by insulation failure. It has become accepted practice to design the electrical system with sufficient flexibility so that a defective portion of the system may be disconnected and the remainder kept in service.

Power systems are designed within reasonable limits to provide sufficient insulation, clearances, etc., to prevent faults; however, a certain number of faults (the surge current to an electrode under faults conditions, such as during arc flash and load short circuits) must be tolerated during life of the system. Every system is subject to short circuits and ground faults; these should be removed quickly. Even with the best possible design, materials tend to deteriorate; dust, dirt and atmospheric residue accumulate and the likelihood of a fault increases with age. Human error and equipment abuse also contribute.

There are many features to consider in the selection of a protective device for a power system. In addition to adequate short circuit protection; it must also provide a means of switching circuits under normal operating conditions. These switching devices should fulfill two basic functions:

1. It should be able to be safely closed on rated load current.

2. It should be capable of interrupting load currents to which it may be subjected.

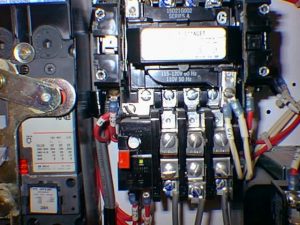

The two basic devices used for switching are circuit breakers and switches. Two basic devices for automatically interrupting excessive current are circuit breakers and fuses. Circuit breakers are combined switching and overcurrent protective devices.

Breakers and fuses are designed to interrupt the power circuit under overload and short circuit conditions to protect the not sufficient to cause the normal protective device to open. Molded-case circuit breakers, low-voltage (600 volts or less) power circuit breakers and fused pressure contact switches with automatic opening features can be equipped with auxiliary trip devices which operate in conjunction with remote sensors for ground fault protection. Time delay features can be provided with these auxiliary trip devices. When properly calibrated, this time delay allows the device closest to the fault to trip sooner than upstream devices, thus interrupting only that portion of the electrical system in trouble.

HOWEVER,

The only function of an OCPD that matters when it comes to an arc flash, is the instantaneous setting and how fast can a breaker open the circuit and stop the current flow to the fault. The actual mechanical speed of the mechanism to open the contacts, stopping the current flow. You cannot make this any faster than designed even if you wanted to. Only current limiting fuses are faster than a 1 cycle molded case circuit breaker.

TYPES OF PROTECTIVE DEVICES

Fuses

The use of fuses in electrical circuits is much like those safety valves on steam boilers. When steam pressure in a boiler rises so high that it is unsafe, the safety valve opens to relieve the pressure. In electrical circuits, before the current becomes more than the wires can stand without overheating and burning the insulation, the fuse burns out, melts or blows; this opens the circuit to prevent further damage. (The circuit opens when a piece of soft metal melts due to the heat generated by excessive current.)

Fuses are made in many different styles and sizes for various voltage and current ratings. The importance of having fuses of proper size and type is apparent.

Circuit Breakers

The low-voltage power circuit breaker may be used in an electrical circuit to interrupt fault currents, provide overload protection and to function as a switch to open and close the electrical circuit.

Molded-Case Circuit Breakers

A commonly used device for low-voltage circuit protection is the molded-case circuit breaker. They are available in a wide range of sizes and rating and have many applications. Molded-case breakers are normally applied where a resettable circuit-interrupting device is needed.

Molded-case circuit breakers are used to interrupt fault currents, provide overload protections and to switch the electrical circuit. Many breakers open in 1 cycle for maximum protection. The speed of the opening/tripping is determined by the design of the breaker and type.

Molded-case circuit breakers can be equipped with ground fault interrupters.

Ground-Fault Interrupters

Molded-case circuit breakers without ground-fault interrupters do not provide reliable protection from line-to-ground faults because of widely varying ground-path impedances, including the arc itself in arcing ground faults. As a result, conventional overcurrent devices may see the ground fault only as load current.

The basic principle of a ground-fault interrupter is to sense current leakage to ground and then cause an interconnected overcurrent device to trip open the faulted circuit.

Protective Relays

Protection against the various types of abnormal conditions that may occur in the circuit is, in many cases, provided by protective relays, which actuate the opening of circuit breakers or switches. The abnormal condition initiates the operation of the relay, which opens or closes an auxiliary control circuit, which in turn trips the switch or breaker mechanism. I will cover in much more detail the protective relay in higher voltage circuits in a later blog. We could talk about this subject for years and never run out of material to cover.

Thermal Relays (TIME DELAY)

Thermal relays are made in several forms, depending upon the manufacturer. They provide inverse-time overload protection. (The greater the overload, the shorter the length of time required for the relay to function.) The two most widely used thermal relays or motor overload relays are the melting alloy type and bimetallic type relays.

In the melting alloy, or solder pot type, overload relay, a heating element melts a bond of eutectic (easily melted) alloy located within the relay. When the alloy melts, it allows a plunger to rotate, releasing a spring-loaded trip slide.

Bimetallic type overload relays work on another principle. In this type of relay, heat causes the deflection of bonded metallic strips, which have different rates of expansion. As heater current increases, the bimetallic bends until it actuates an integral toggle trip switch.

Thermal relays are extensively used in connection with magnetic switches for the overload protection (time delay) of electric motors.